Hot Chamber Die Casting

- Home

- Hot Chamber Die Casting

ALUMINIUM DIE CASTING

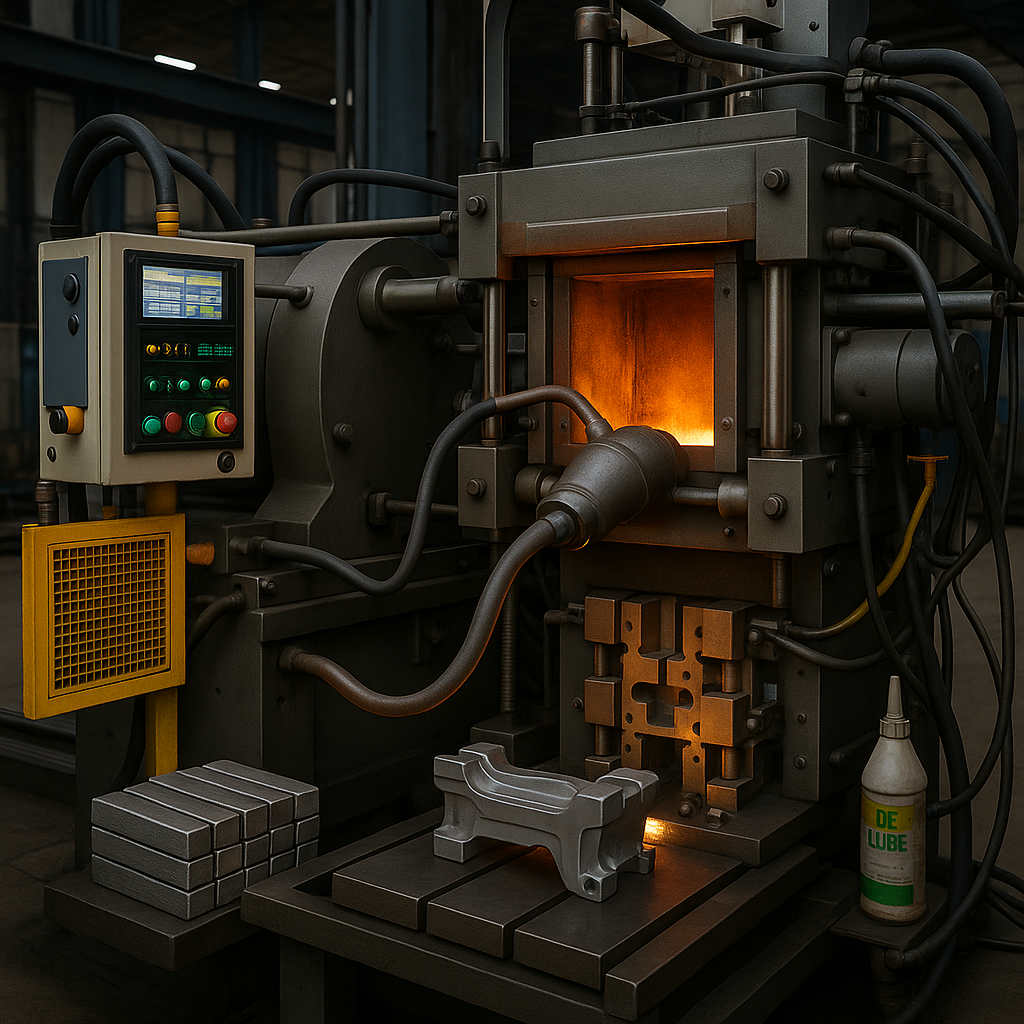

Hot Chamber Die Casting

Hot chamber die casting is engineered for speed and efficiency. By immersing the injection system directly into the molten metal bath, this process eliminates transfer delays, shortens cycle times, and reduces cost per part. It is best suited for zinc, magnesium, and other low-melting alloys where fast, consistent production of small-to-medium parts is critical.

Why Hot Chamber Die Casting Stands Out

Faster cycle times compared to other casting methods

Lower operational costs through streamlined processes

High-volume production with minimal scrap

Ideal for small and medium-sized components

Efficiency Built Into the Process

Direct injection system immersed in molten alloy

Reduced metal handling and oxidation loss

Consistent shot-to-shot repeatability

Supports thin walls and detailed geometries

Where Hot Chamber Creates Value

Zinc alloys for strength and precision at scale

Magnesium components needing lightweight performance

High-volume production runs requiring speed

Consumer, automotive, and industrial parts with fine detail

Explore other Die Casting Technologies

Hot Chamber Die Casting

High-speed manufacturing process ideal for zinc, magnesium, and other alloys requiring rapid, repeatable precision.

Hot Chamber Die Casting

High-speed manufacturing process ideal for zinc, magnesium, and other alloys requiring rapid, repeatable precision.

Hot Chamber Die Casting

High-speed manufacturing process ideal for zinc, magnesium, and other alloys requiring rapid, repeatable precision.